Designed to be disrespected

We don’t just say WaterHog is tough — we engineer it that way. Thanks to our vertical integration, we control every step of the process — ensuring consistent quality, durability, and safety. Here’s what’s happening behind the scenes (or inside the factory, to be exact).

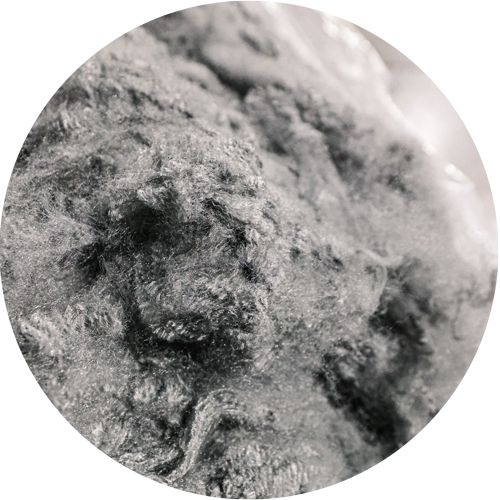

STEP 1 / FIBRE MIXING

Recycled. Refined. Ready.

It starts with recycled PET bottles, shredded and blended to perfection. We mix them to get just the right texture and colour — think of it like rugged confetti with a mission.

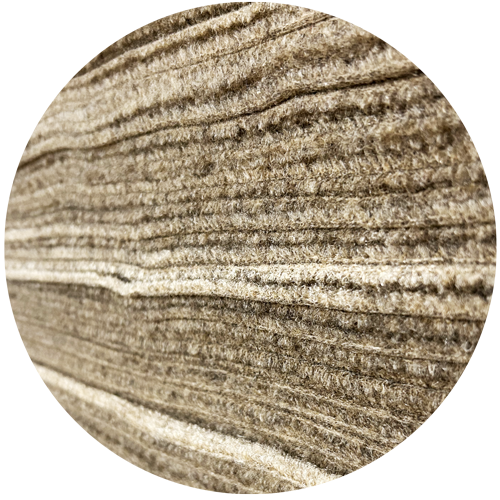

STEP 2 / FABRIC FORMATION

Where Strength Takes Shape

Fibres are pulled, aligned, and punched into one solid sheet. Thousands of fine needle punches lock it together into a dense, high-performance surface that can take a kicking.

STEP 3 / RUBBER BACKING

Backed by Quality

While the fabric takes shape, we produce the rubber backing in-house — using industrial-grade nitrile with over 20% recycled content. No fillers, no PVC — just durable, flexible grip that stays flexible down to -20 °C and grips any floor without cracking or crumbling.

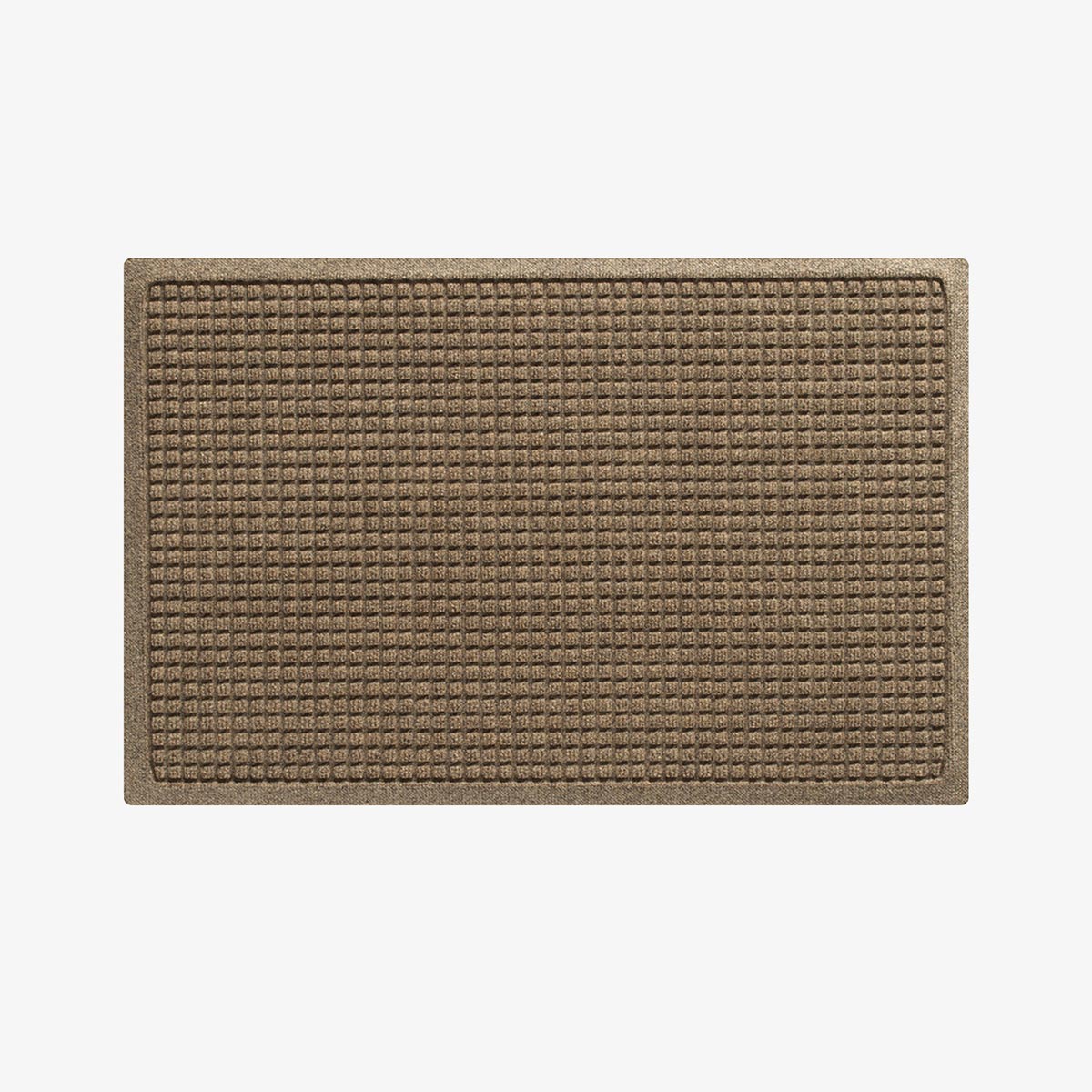

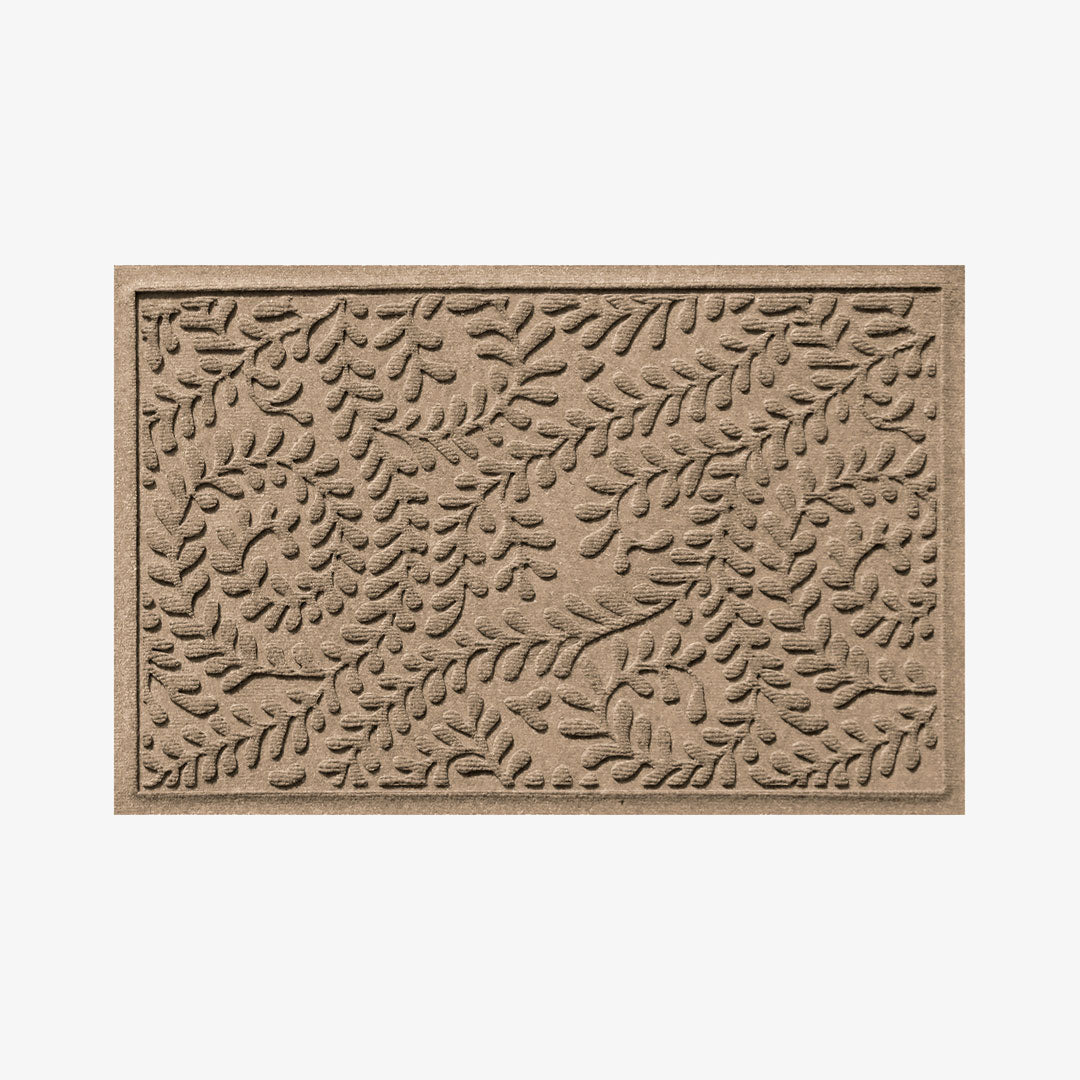

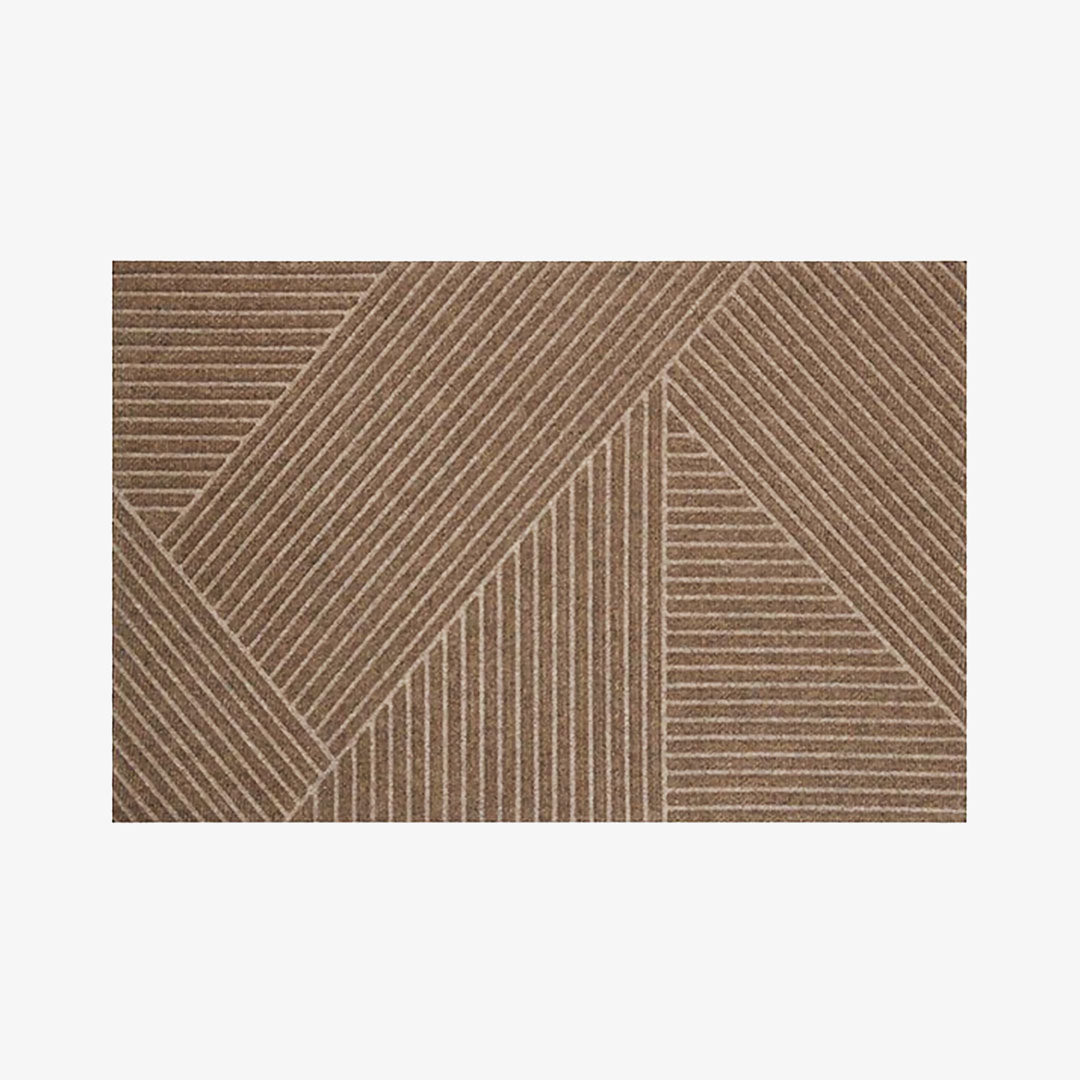

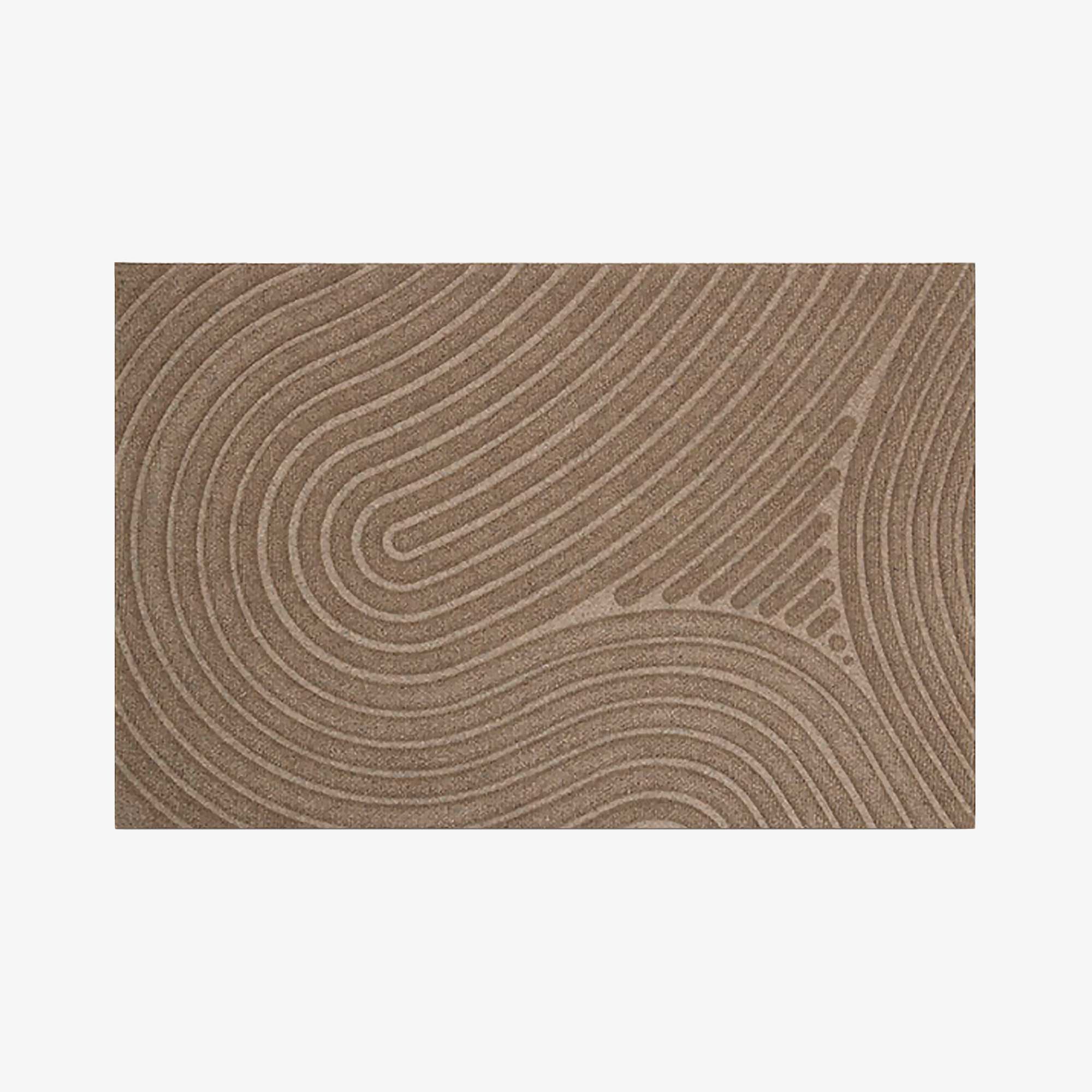

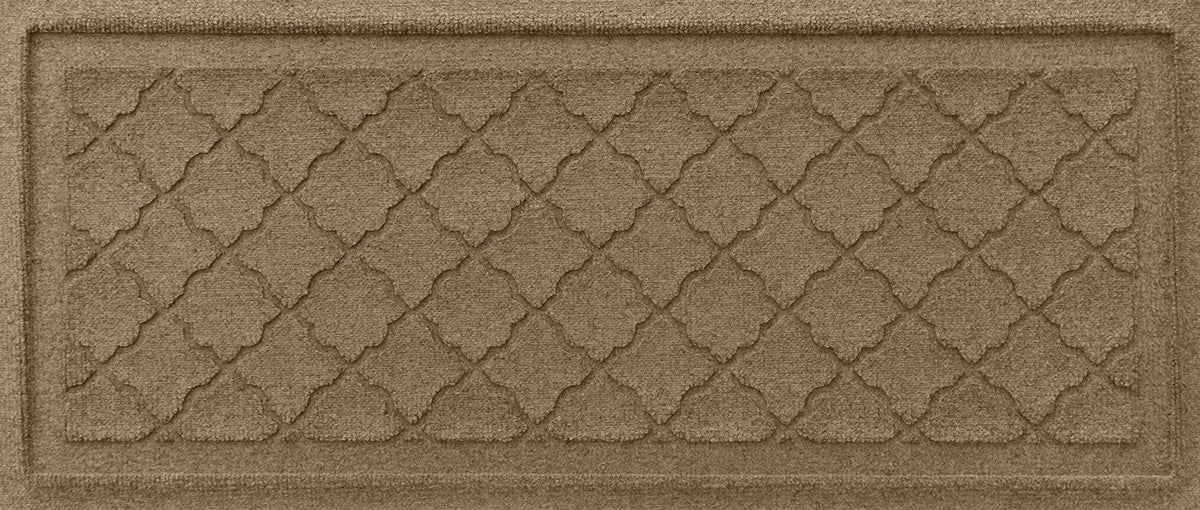

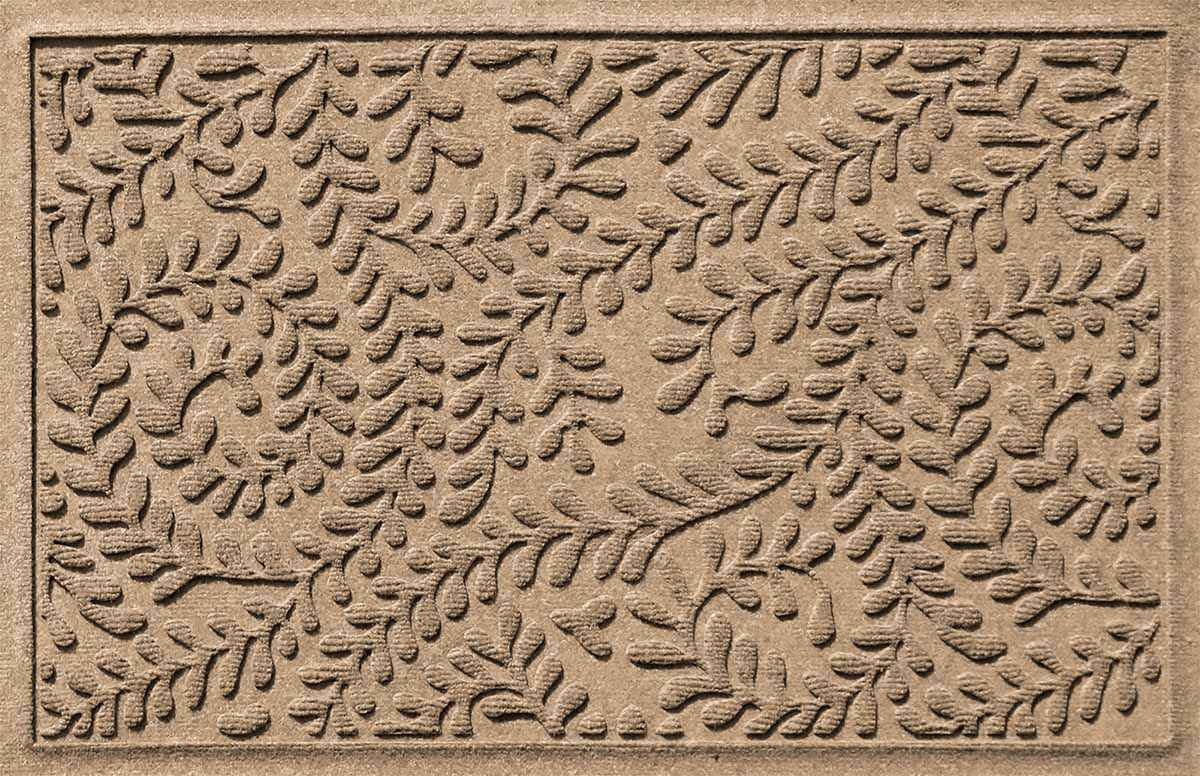

STEP 4 / PRESSES

Pressed to Perform

We press every mat using custom moulds that create our signature bi-level design. It’s how we trap dirt below the surface, keep the top looking clean, and bond it all to a solid rubber base that doesn’t curl, shift, or quit. This step also vulcanizes the genuine WaterHog logo into the backing — proof of authenticity and quality in every mat.

STEP 5 / CUT

Final cut!

After pressing, each mat gets a precise final cut to ensure all layers — fabric and rubber — are perfectly aligned and cleanly finished. Nothing sticks out, nothing left to chance. It’s the last touch before our quality check and your mat is ready to ship.

This isn’t your average doormat.

It’s pressure-forged, fibre-punched, rubber-backed resilience — ready to take a beating so your floors don’t have to.

Shop the mat that’s built different from the ground up.

SHOP YOUR MAT NOW